Article by Mike McNessor and published by Hemmings. The original article complete with ads and popups can be found here

While the Corvair did bring turbocharging to the masses in ’62, the Turbo Air 6 was Chevrolet’s name for the naturally aspirated base engine that made its debut in ’60. Initially, the six displaced 140-cubic inches but, in ’61, the bores were enlarged from 3.375 inches to 3.437 inches raising the engine size to 145 cu.in. In ’64, an increase in stroke from 2.6-inches to 2.94 inches upped displacement to 164-cu.in.

The Turbo Air 6’s design was influenced by Volkswagen’s flat four but inspired by aircooled, aircraft and tank engines that Chevrolet’s Chief Engineer Ed Cole was familiar with.

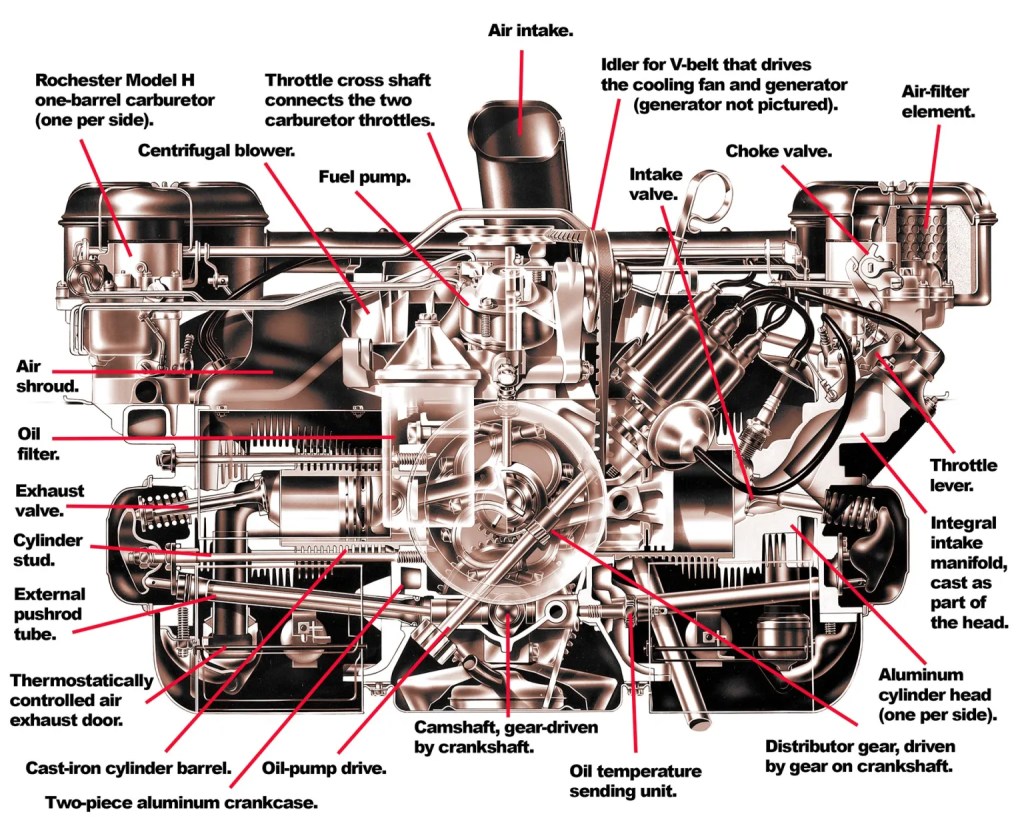

The foundation for the Turbo Air 6 was a two-piece cast-aluminum crankcase with a crankshaft that rode in four main bearings. The camshaft was located below the crankshaft and driven by gears off of the crank. Hydraulic valve lifters were standard issue and activated hollow pushrods concealed inside steel tubes on the outside of the engine. The rocker arms were lightweight stamped steel like those used on Chevrolet small-block and big-block engines.

Each cylinder was contained in a separate, finned, cast-iron barrel and the opposed banks of three were each capped with a cast-aluminum, overhead-valve head. The heads had cast-in cooling fins as well as integral intake manifolds and were fastened with studs through the cylinder barrels. A pair of Rochester one-barrel carburetors — one for each bank of cylinders — fed fuel and air to the engine.

A forced-air system cooled the Turbo Air 6, at the heart of which was an 11-inch diameter centrifugal engine blower mounted horizontally on the top center of the engine. With 24 vanes and driven by a V-belt off the crankshaft, via an idler, the blower could produce 1,850-cfm of air flow at 4,000 engine rpm. Sheetmetal shrouds encased the engine to keep the air flowing over the cooling fins and thermostatically controlled doors on the lower portions of the shroud allowed hot air to escape. Early engines with steel blowers had a tendency to throw V belts so, in ’64, Chevrolet replaced the steel unit with a lightweight magnesium blower. Something that all Corvair engines have in common with Porsche sixes? Yep, oil leaks — from the pushrod tubes and crankshaft seal are pretty common.

Corvairs have always been overshadowed by Camaros and Chevelles in the Chevrolet hierarchy and have more in common with VWs and Porsches. These engines are a breed of their own, but plenty of support and excellent parts availability will allow you to keep one of these airheads running dependably enough to serve as an everyday driver.

Parts List

- Air Intake

- Idler for belt that drives cooling fan and generator

- Choke valve

- Air filter element

- Intake valve

- Throttle lever

- Integral intake manifold, cast as part of the head

- Aluminum cylinder head (one per side)

- Distributor gear, driven by gear on crankshaft

- Oil temperature sending unit

- Camshaft, gear-driven by crankshaft

- Oil-pump drive

- Two-piece aluminum crankshaft

- Cast-iron cylinder barrel

- Thermostatically controlled air exhaust door

- External pushrod tube

- Cylinder stud

- Exhaust valve

- Oil filter

- Fan shroud

- Rochester Model H one-barrel carburetor (one per side)

- Throttle cross shaft connecting the two carburetor throttles

- Centrifugal blower

- Fuel pump

Leave a reply to Laurence Jones Cancel reply