You may be new to Corvairs and maybe stumbled upon a forum post, Facebook conversation or maybe saw a Corvair locally with a weird looking setup with a tag that reads “Supercharged by Judson”. You may have then asked yourself, “What is a Judson Supercharger?”. You may be reading this and saying, “Wait! I can supercharge my Corvair?!”

First, a brief history of the Judson Company.

The Judson Supercharger was the brainchild of the Judson Bros, W. Haddon and Charles. They manufactured farm equipment in Pennsylvania. After starting with a Ford Flathead V8 model, the company saw its biggest success in 1956 with a supercharger kit for the Volkswagen Beetle, which expanded into a wide range of popular cars in the following years. With the popularity of engine modification by young enthusiasts, they began to design Supercharger kits for other European makes and, with the initial fever of the Corvair in the early 60’s, modified their VW kit to accommodate the Corvair. Ad’s for the Judson Supercharger could be found in the classified and back pages of many of the popular car magazines of the early to mid 60’s.

Judson’s varied from other Superchargers of the day Judson used a sliding-vane, rotary type, different from the Roots or centrifugal designs that were more common. They were designed to provide a consistent boost in power throughout the engine’s normal operating range, not just at higher RPMs.

If you want to take a deeper dive into the Judson supercharger and its various applications and operation, read this article by Hemmings.

For the Corvair, we are going to switch gears and share this article from Bob King which was initially published in the Lehigh Valley Corvair Club newsletter from March 2021.

The purpose of this Tech Article is more of a documentation of the Judson supercharger offered to give more power to early Corvairs. (40-45 HP gain). Judson made superchargers for all kinds of smaller engine cars for the same reason. Most of them were imports. Triumphs, VWs, Volvos, TR3’s etc.

The Supercharger Unit

The Judson unit is a sliding-vane-supercharger. It provides a lot of power for its size and is extremely simple in design. It provides power when you need it, much like a turbocharger.

The Judson supercharger is a positive displacement pump which uses blades – vanes – sweeping the inside of a cylindrical case to move the air to fuel mixture. It is similar to a Roots type blower except for one important difference. By using a small inner drum set eccentrically into the outer case, the volume of the air slug between each pair of blades is decreased as it moves through the casing. This results in compression inside the blower itself as well as the intake manifold. And when you compress by decreasing volume, you convert the heat of compression into useful pressure energy so that it requires less power to compress a given amount of air.

There are only a few major parts: a manifold base that drops over the existing Corvair carburetor studs, a ribbed cylindrical case that bolts on to the base, and an internal drum that spins inside the case. The case has two end covers with bearings that support the rotating drum. Four sliding vanes ride up and down in slots cut into the periphery of the rotating drum. They are made of a phenolic material cut to a rectangular shape. Then there is a pulley mounted on the end of the shaft. There is also an external oiler system for lubricating the vanes.

Carburetor

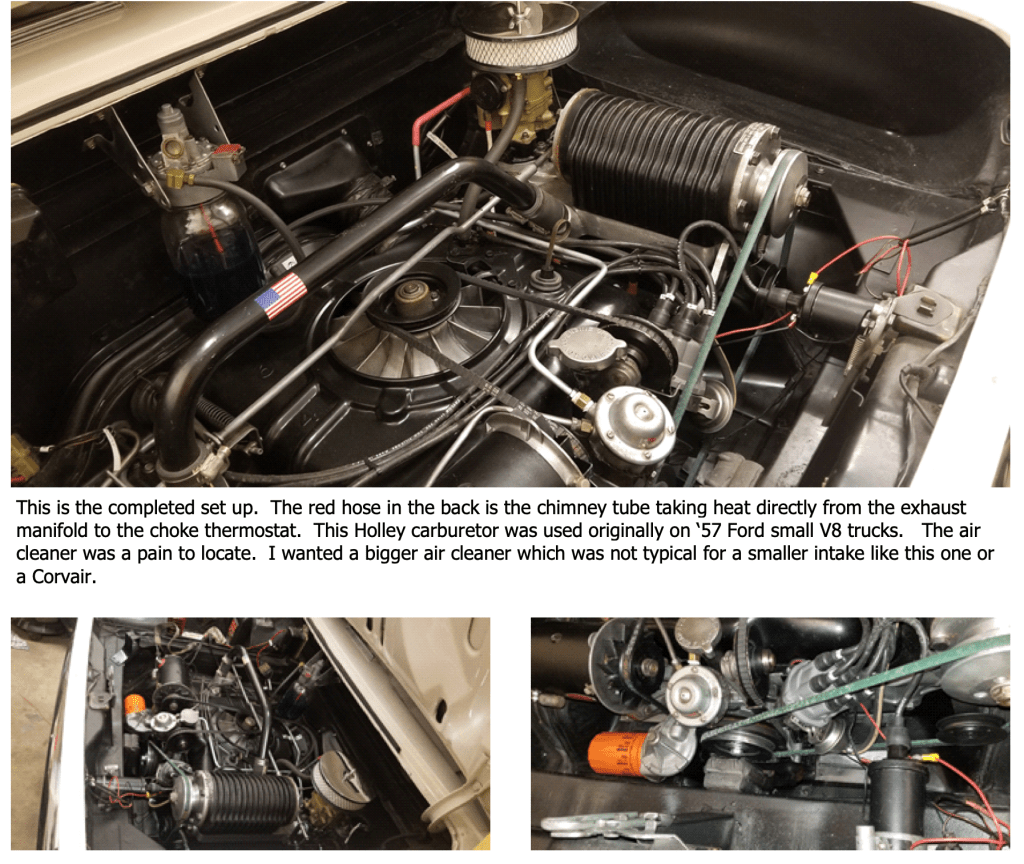

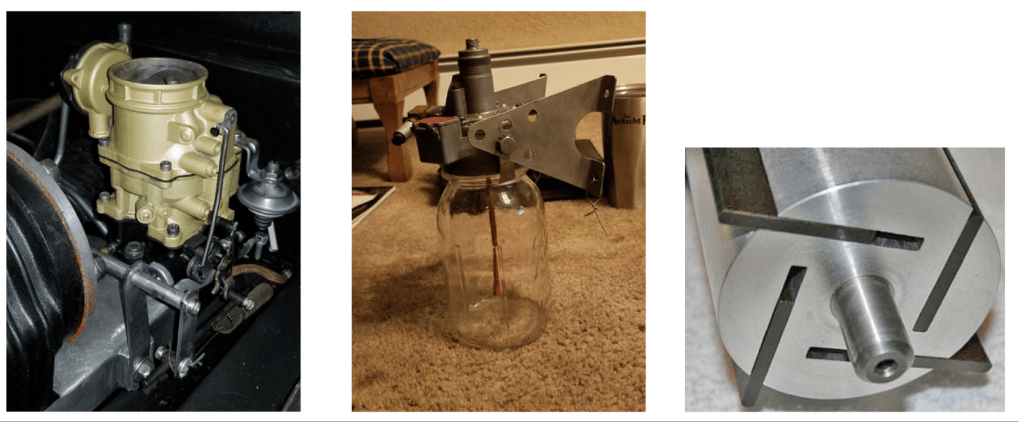

The Judson supercharger is a draw-through setup, meaning that the carburetor is located at the supercharger inlet rather than the outlet. For the Corvair, a two-barrel Holley 2110 carburetor is used. The Holley 2110 was original equipment on Ford 272 CID truck engines for 1956 and ‘57. It is a derivative of the famous Holley 94 carburetor which Holley designed and manufactured for Ford Motor Company from 1938 to 1957. Some of them even have the Ford logo cast into the carb body.

Rebuild kits are available from a couple vendors. This carburetor style remains popular and is often used on hot rods engines equipped with dual or triple “two barrels”. I have two 2110’s -one cast Holley, one Ford, both identical but for the labeling.

The Holley 2110 consists of three main castings. The base is cast iron and has the two throttle plates, idle screws, and throttle lever. The aluminum center section has the venturi, main jets, accelerator pump assembly and bowl.

The aluminum top has the float assembly, choke shaft and fuel inlet. The power valves used in the carburetor are the high speed enrichment type.

The standard valve is calibrated to come on at 8.3 HG. My understanding is, at higher speeds when you hammer down, the vacuum will close the valve letting fuel in to enrich the charge. The higher the HG value, the sooner it comes on. If you are getting too much fuel, you go to a 4.5 or 3.5 HG. If you see black smoke you’re over enriching. The spark valve is located in the base of the carb. It is visible from the outside of the carburetor. When accelerating, manifold vacuum drops and the calibrated spring in the spark control valve begins to close and shuts off the vacuum to the distributor. That retards timing. Venturi vacuum acts as sort of a buffer keeping vacuum advance from doing a complete retard. When manifold vacuum rises again, the spark control valve opens again thus advancing the distributor.

The choke is an automatic style almost identical to the kind found on Carter side-draft carbs used on turbo Corvairs. It uses an aluminum stove pipe tube to draw vacuum from the other end of the pipe positioned at the exhaust manifold. The stove pipe feeds heat to the thermostat coil, slowly opening the choke plate. There is also a vacuum piston in the assembly that pulls the choke lever towards an open position when accelerating cold. You can see the fuel inlet for the bigger ¼ flare tubing, There is a component used on the Holley that is not found on Corvair carburetors. This is called a dash pot.

Mounted on the top of the carburetor, it had a unique job of slowing down the rapid closing of the throttle. Mainly used for automatic transmission appli- cations, it helps prevent stalling due to rapid closing of the throttle. Not an issue with a Rochester but necessary for the Holley.

The Oiler

The vanes of the drum need lubrication because they ride on the inner surface of the supercharger case. They need to be lubricated to prevent damaging the housing walls and hurting compression, so an oiler was required. Judson met this requirement by including an oiler system marketed by the Marvel Mystery Oil Company in the supercharger kit.

Consisting of an oil bottle, hose and fittings, it feeds a measured amount of oil into the incoming fuel-air mixture.

The Marvel Mystery Oil Companycalled this device an “inverse oiler”.

That means as manifold vacuum goes up, the oil delivery slows. As it goes down as in accelerating, the oil delivery increases. You don’t need as much oil with low boost pressures. There is a window on the top of the oiler. When you remove the top cap, there is a knob you turn to increase or decrease the oil flow. It works like a charm.

You can see drips behind the view port. If you time the drips as recommended, you won’t see smoke. It takes a couple drips per second.

Of course, the Marvel Mystery Oil people wanted its customers to use Marvel Mystery Oil in their oiler system. But Judson disagreed. Marvel Mystery Oil is technically not a lubricant as much as a cleaner. I have been experimenting with 25% 30 weight oil for now. If you see exhaust smoke you are running the output of the oiler too high.

Clack! Clack! Clack!

The vanes inside the supercharger rely solely on centrifugal force to keep them in contact with the interior walls of the case in which they spin. They aren’t spring-loaded. So, at low RPM, they bounce around on the ID of the supercharger housing. They make a horrendous clacking sound. At low RPM, it actually sounds like the engine is falling apart. It is not the most performance minded sound to hear.

However, when the RPM is high enough, the vanes are held outward by centrifugal force and thus remain in contact with the ID of the supercharger housing. Now the clacking stops.

Installation

Short Story – It fit in like a glove. But I don’t want to say it was without challenge. Getting the carb set up to run right was horrible! At first, it wouldn’t idle below 2,500 RPM. I actually had my ear muff hearing protection on, it was so loud. Not just the engine but the supercharger sounds like you’re next to a quarry rock crusher! But with some tuning, it now runs fine.

I figure I bumped the HP from 110HP up to 160HP which is not shabby for an early model. It’s a 4 speed so it’s a blast rowing through the gears.

Thanks for reading and as always

……. Keep ON Corvairing!!!!

Have a Judson story or a Corvair engine modification story? Did we, or Bob miss anything in this article? Let us know in the comments!

Leave a comment