This article by Bob Helt appeared in the November 1981 issue of the CORSA Communique magazine. CORSA members can read the original article, which includes several additional photos, by logging into the CORSA website.

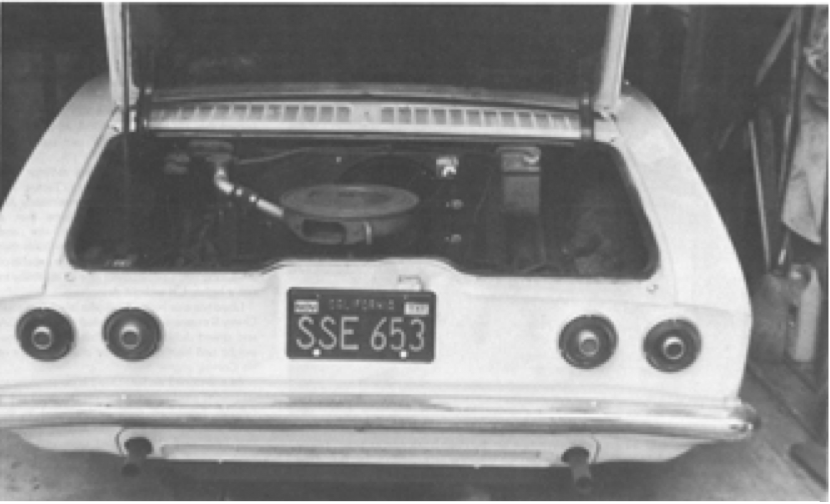

The 1966 Corvair Monza appeared to be in almost factory stock condition as it sat in Lloyd’s garage. Only the twin exhaust pipes exiting through the rear grill gave a hint of the unusual engine I was about to see. The owner told me of his water-cooled Corvair engine design as we walked toward the car. Despite the fact that I had previously heard of his work, I was totally unprepared. Not just a water-cooled Corvair engine, but a technical marvel of engineering and innovation.

The designer and builder is Lloyd M. Taylor. Lloyd pioneered an engine fabrication technique for the 1947 Crosley automobile. Instead of a cast iron block and cylinder head, the Crosley 4 cylinder engine was made from sheet steel which was cut, formed, and welded together. This same fabrication technique was used to make the six water-cooled cylinder/cylinder head assemblies for use on his Corvair engine. These assemblies, designed and built by Lloyd, are made from sheet steel pieces which have been cut, stamped and formed to fit.

When all the pieces of metal are thus shaped, they are held in a fixture and furnace brazed (welded) together using a special process that Lloyd has developed. Basically, all the parts are held in place and passed through a 2100 degree F furnace on a conveyor belt to complete the brazing operation. Welding the outer water jacket in place finishes the individual cylinder assemblies.

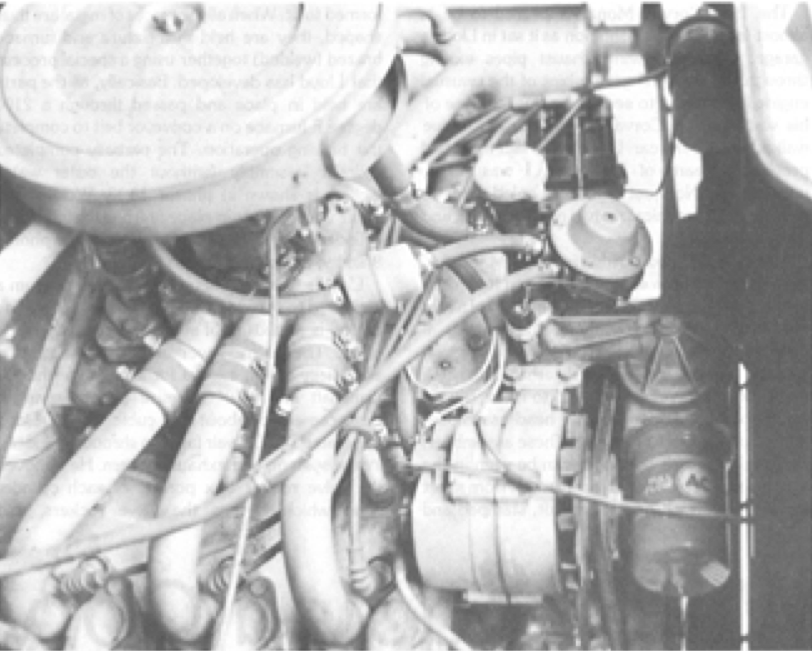

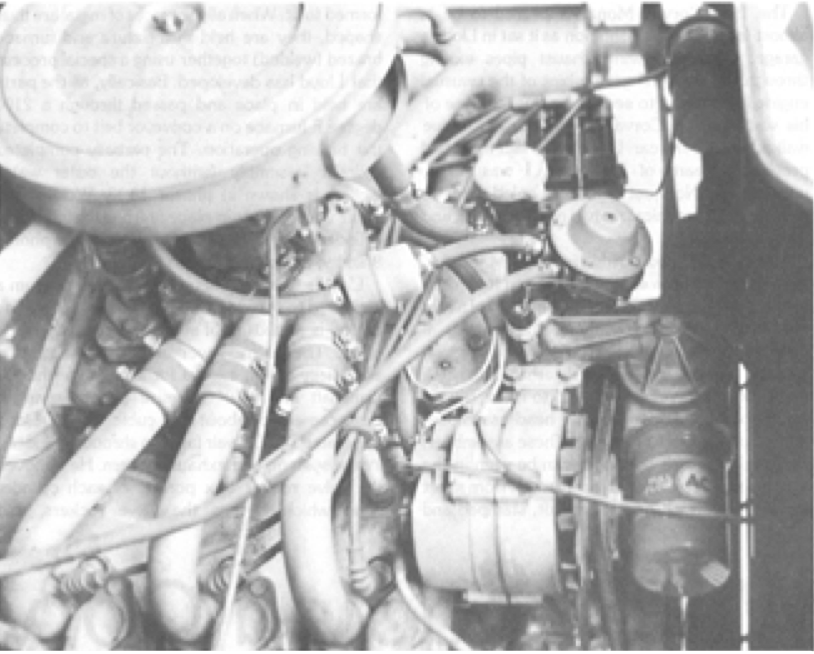

Lloyd’s Corvair engine is a 1963 he got from a junk yard to rebuild without disabling his car. The engine is a mixture of stock and specially made parts. The entire lower end of the engine is essentially stock, except for a mild aftermarket camshaft and .060″ oversize pistons giving a displacement of about 151 cubic inches. Lloyd eliminated the Corvair fan, top shroud, cylinders, intake system, and exhaust system. He removed the valve rocker box portion of each cylinder head which houses the valve rockers, and discarded the rest of the Corvair heads.

A new water-heated intake plenum was designed and built for a single centrally-mounted two-barrel carburetor. This intake plenum also serves as a new top cover for the engine. Six individual intake pipes, one for each cylinder, were made. The alternator was relocated to allow it, and the new water pump to be driven by a V-belt traveling in a single plane. The water pump and housing are mounted just below the alternator.

Twin water distribution plenums distribute the water to the six cylinders. A new set of exhaust headers was built to handle the relocated exhaust ports which are now located at the top of the cylinders, just adjacent to the intake ports. Normal Corvair exhaust exits at the bottom of the cylinder head. A separate muffler is used for each cylinder bank.

The combustion chamber is not specifically Corvair, but is Lloyd’s own design based upon VW combustion chambers. Extra large GM valves are used to accomplish a free-flowing entry and exit. The cylinder and combustion chamber are an integral design (being brazed together) which eliminates the standard head gasket.

After the three fabricated cylinder/head assemblies are bolted in place on each bank (with bolts replacing the head studs), the modified valve rocker box (removed from the Corvair head) is bolted in place. The valve stems protrude into the valve rocker box.

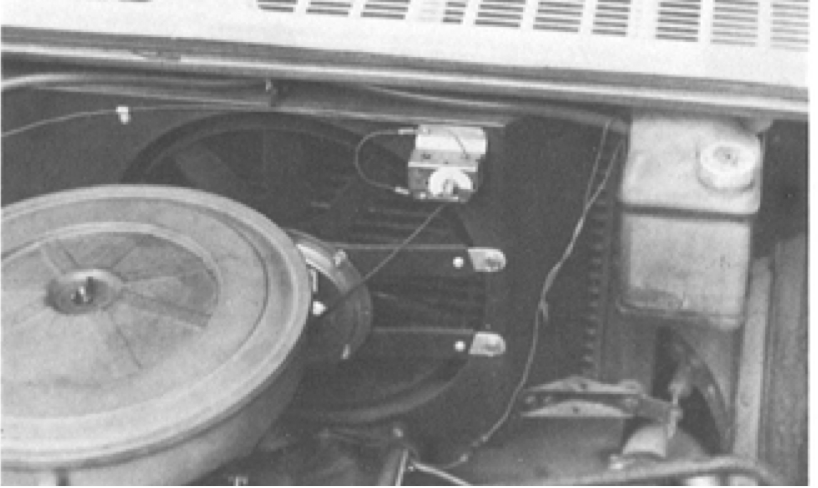

The radiator is mounted up against the air intake at the front of the engine compartment. An electronically-operated cooling fan is thermostatically controlled by the coolant temperature. Coolant is circulated by a belt driven pump to right and left side distribution plenums which direct the water to the six cylinders. Coolant exiting the cylinders is gathered in the intake plenum to heat it for better mixture distribution and then is sent to the top of the radiator for cooling.

Lloyd has put about 7,000 miles on his water-cooled Corvair engine and reports exceptional performance. He regularly gets 23 MPG in the city and 33 MPG highway. The engine has an 11:l compression ratio, and performs satisfactorily on unleaded regular without detonation. He attributes this ability to run detonation-free to his unique fabricated steel design which has uniform metal thicknesses that can be uniformly cooled.

By contrast, a cast iron block and head has large variations in metal thick nesses which cause non-uniform cooling and thus hot spots. According to Lloyd, these hot spots are the cause of most detonation problems. Thus in his design, thinner and more uniform metal dimensions promote better cooling which eliminates hot spots. The elimination of hot spots reduces the tendency to detonation and allows the use of higher compression ratios than would be possible in a cast iron design.

Lloyd’s 151 CID Corvair engine produces a substantially flat torque curve of 150 lb-ft from 3500 RPM. Horsepower starts high and rises to a remarkable 198 HP at 7000 RPM. At 5200 RPM his engine puts out one HP per cubic inch displacement. Total engine weight including radiator and coolant is only 250 lbs. according to Taylor. The stock Corvair engine weighs approximately 326 lbs. for comparison. Taylor claims that a fabricated steel engine of given size and displacement would weigh about two-thirds that of its cast iron brother. It would also be capable of producing more horsepower due to its ability to run a higher CR without detonation. Higher CR’s means greater power and engine efficiency.

Lloyd has also built a 4-cylinder fabricated steel Chevy II engine which is installed in a 1958 MGA and driven daily. It also exhibits the same low weight and high performance characteristics of his Corvair engine.

As mentioned earlier, Lloyd is no stranger to fabricated steel engines, having designed the 4 cylinder fabricated steel engine used in the Crosley automobile from 1947 to 1952. He feels that fabricated steel engines offer benefits of lower weight, lower production costs, greater efficiency through higher usable CRs, and lower exhaust NOX emissions because hot spots have been eliminated. His two running engines provide real-life proof to his claims.

What do you think?

- Corvair blasphemy or ingenuity?

- Lloyd’s Corvair was (is?) in California. Have you ever seen it?

- Have a Corvair story, article or tech tip you want to share?

Let us know in the comments!

***Last min. ed. note***

Today is the Old Car Picnic in Golden Gate Park in The City. It’s pay at the gate, so if you are looking for a last minute event to attend, it should be a beautiful day at the park. $40 cash at the gate. Spectators can attend for free.

We also hope that you all attending Gabe’s welding workshop at Sterling Restorations today have a great time. We know that four SFBA members signed up to attend. Send us a review of the class.

Leave a comment