Engine cooling. It is topic that comes up frequently in conversations among Corvair people. There are many tips and tricks to get that Corvair to run just a few degrees cooler. Some are quite expensive and some require quite a bit of ingenuity. There is, however, one easy, cheap, and somewhat quick method to keep that engine running a little cooler that you can do at home with some simple tools.

Unlike our water pumper friends, we rely on constant cool airflow to keep our engines from overheating. This cooling is accomplished with the fan drawing in air and forcing it down over and through the cooling fins of the engine. This force also pushes the hot air generated by the engine out of the bottom of the lower shrouds or into the cabin to keep you warm on cold days.

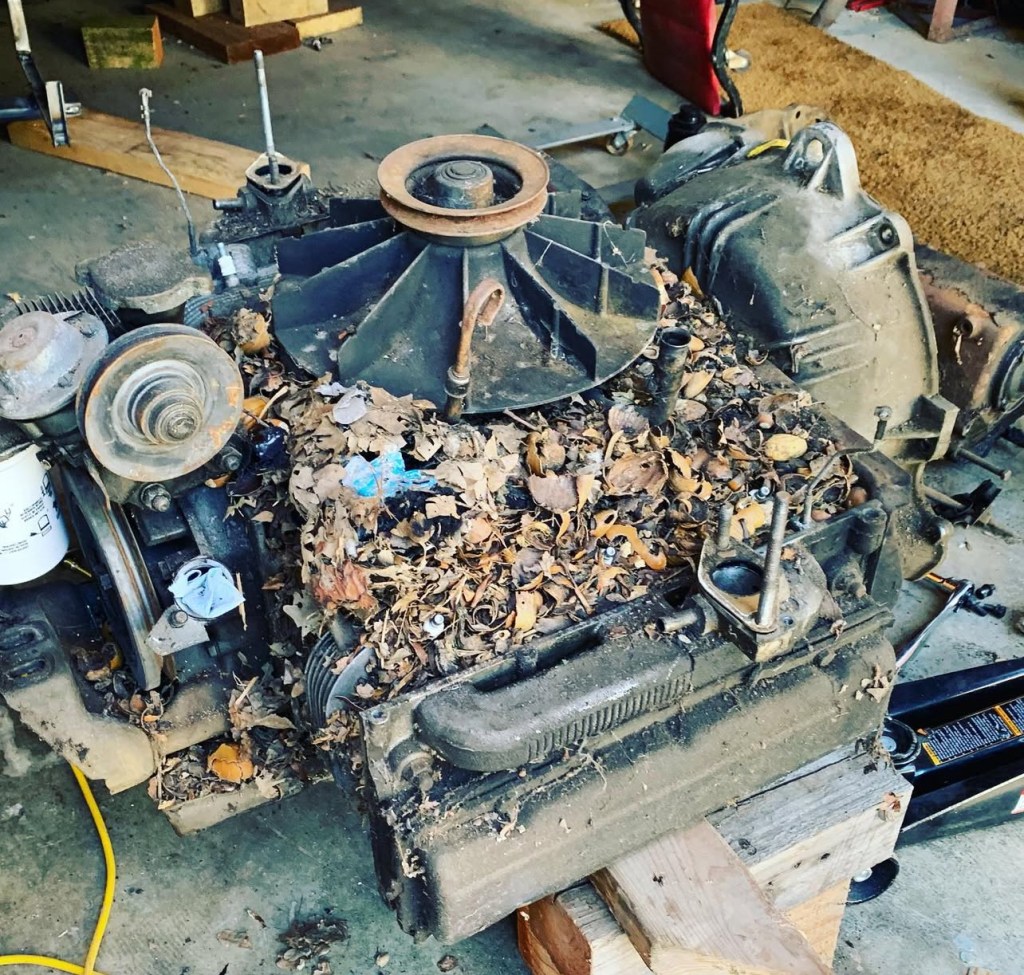

When you pull off the top engine shroud, you should be able to look through the fins of the cylinder heads, piston jugs and oil cooler. Over time, many things can cause obstructions in cooling resulting in a hotter running engine. Grime, leaves, old rags and rodent nests are often the main culprits of air blockage.

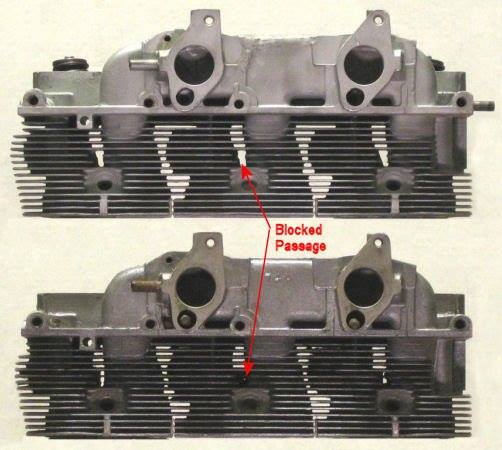

GM was to blame as well, as aluminum heads at the factory were often left with “slag” resulting in air passage blockage. “Slag” is the leftover aluminum from the casting process. With a flashlight looking down through the fins, you can see the thin material between the fins or at the ends of the cylinder heads.

To remove this material, all you will need is a hacksaw blade, a flashlight and (optional) a shop vacuum cleaner.

Remove all of your linkages, carbs, spark plug wires and top shroud. Once the engine is exposed, the first thing you will want to do is inspect for any visible debris and remove or vacuum it off of the top of the engine. It is also recommended to remove the bottom shrouds so the aluminum shavings go to the ground for easier cleanup.

Next, you will want to grab your hacksaw blade. It has been recommended by other Corvair owners to sharpen the edge of the blade so it can puncture more easily through the aluminum slag. Using a Drywall blade is also a popular choice as the end is already pointed and it comes with a handle. Gentle is the way to go here. Sawing aggressively could potentially damage the cylinder heads.

Work the blade through the cooling passages. Some areas may be blocked through, so you may need to punch down a bit to get the blade through. Check every so often with a flashlight to see that the passages are opened up.

When you are finished, under each cylinder head, you should see a small amount of shavings. The above photo is of a cylinder head that had excessive slag.

While the above is an extreme case of what might be hiding under your engine shroud, it is always recommended to inspect the area when you bring that new Corvair home and to check periodically to make sure the airway paths are unobstructed. Your engine will thank you.

Do you have a cylinder head deflashing recommendation we missed? Maybe a story about finding an engine with some surprises under the tin? Let us know in the comments.

Leave a comment